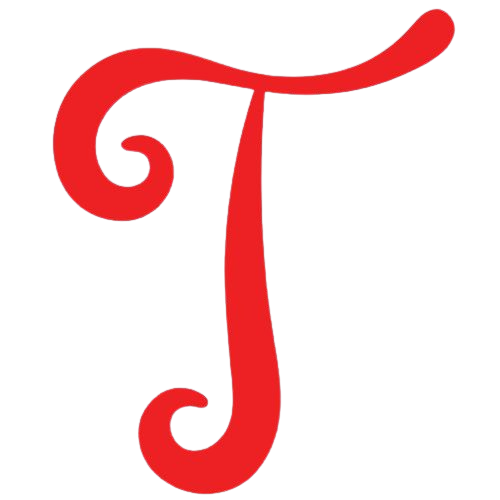

Industrial safety is paramount in modern operations. The ACTT Service Program SP 3-872-009 Shut Down Harness is a crucial tool in this domain. It provides a reliable safety mechanism for various industrial settings.

This harness is designed to prevent accidents and protect equipment. It offers rapid shutdown capabilities in emergency situations. Understanding its features and applications is essential for safety professionals.

Understanding the ACTT SP 3-872-009 Shut Down Harness

The ACTT SP 3-872-009 is a specialized emergency shutdown system. It integrates seamlessly with existing industrial control mechanisms. The harness acts as a fail-safe in critical situations.

It responds to various triggers, ensuring swift action when needed. These triggers may include mechanical failures or process deviations. The system’s primary goal is to prevent accidents and minimize damage.

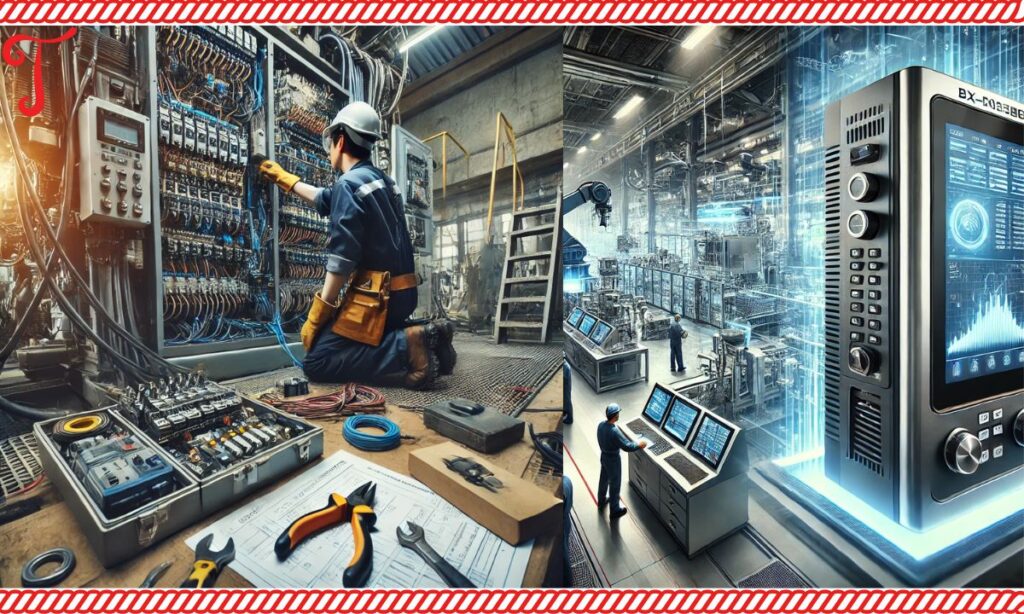

Core Components of the ACTT SP 3-872-009 Shut Down Harness

The shutdown harness comprises several key components. Each part plays a vital role in the system’s functionality. Understanding these components is crucial for proper implementation and maintenance.

The main elements include a control interface and signal receivers. It also features relay systems and a dedicated power supply unit. These components work in harmony to ensure reliable operation.

Design Features

The ACTT SP 3-872-009 boasts several important design features. These enhance its functionality and reliability in industrial settings. The design prioritizes safety, efficiency, and adaptability.

Key features include scalability and modularity. The system is built to withstand harsh environments. It also incorporates redundancy to ensure consistent performance.

Read This Blog: Kane Ryan Fielding Amarillo TX: A Beacon of Community and Innovation in Amarillo, TX

Importance in Industrial Applications

This shutdown harness is crucial in many high-risk industries. It’s particularly valuable in chemical processing and manufacturing. The system’s rapid response capability is its primary advantage.

It can halt operations without human intervention. This feature is invaluable in preventing accidents and protecting assets. The harness significantly enhances overall safety in industrial settings.

Why Implement the ACTT SP 3-872-009 Shut Down Harness in Industrial Settings?

Implementing this harness offers numerous benefits. It enhances safety and compliance in industrial operations. The system provides peace of mind for operators and managers.

It helps companies meet strict safety regulations. The harness also reduces the risk of costly accidents. These advantages make it an essential tool in modern industrial environments.

Enhanced Safety Compliance

Safety compliance is a top priority in industry today. The ACTT SP 3-872-009 helps meet and exceed safety requirements. It provides a robust solution for emergency situations.

By implementing this system, facilities improve their safety profile. This can lead to better relationships with regulators. It may also result in fewer safety-related incidents overall.

Immediate Risk Mitigation

Quick response is crucial in industrial emergencies. The ACTT harness provides rapid reaction to potential hazards. It can detect and respond to problems almost instantly.

This immediate action prevents small issues from escalating. It helps protect both personnel and equipment. The system’s speed is one of its most valuable features.

Minimization of Operational Downtime

Downtime is costly in industrial settings. The ACTT SP 3-872-009 helps minimize this downtime. It does so by preventing major incidents before they occur.

By quickly addressing issues, the system limits damage. This means repairs are often simpler and faster. As a result, operations can resume more quickly after a shutdown.

Cost Efficiency

Investing in safety can lead to long-term savings. The ACTT harness exemplifies this principle. Its upfront cost is offset by potential savings over time.

These savings come from various sources. They include reduced equipment damage and lower insurance premiums. The system can also help avoid costly legal issues.

Read This Blog: BX-4013HWBC: Revolutionizing Industry Standards

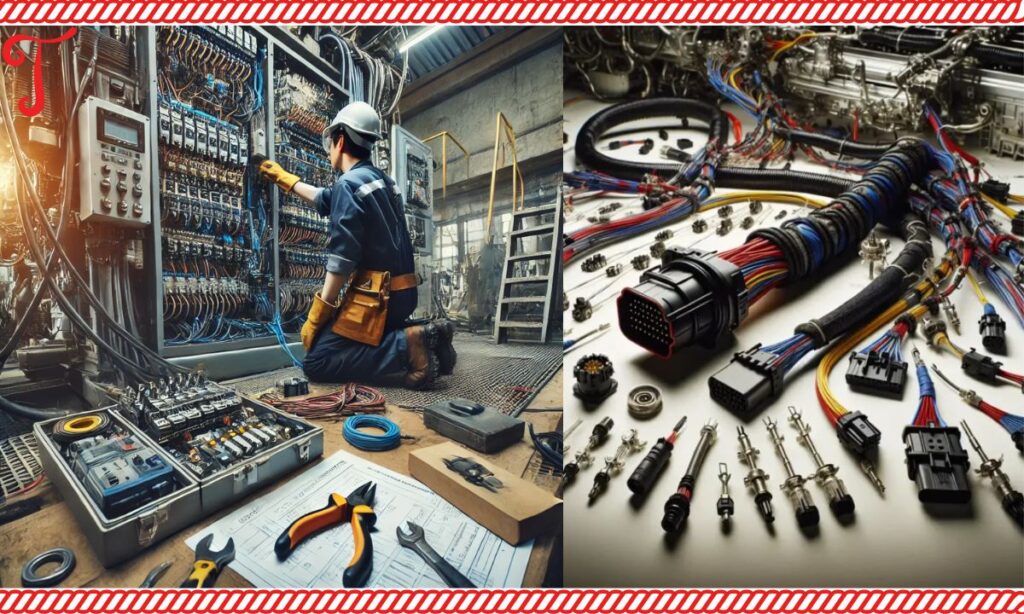

Future-Proofing Operations

Industrial technology is constantly evolving. The ACTT SP 3-872-009 is designed with this in mind. It’s built to adapt to future technological advancements.

The system can be upgraded over time. This ensures it remains effective as safety standards change. It’s a long-term investment in operational safety and efficiency.

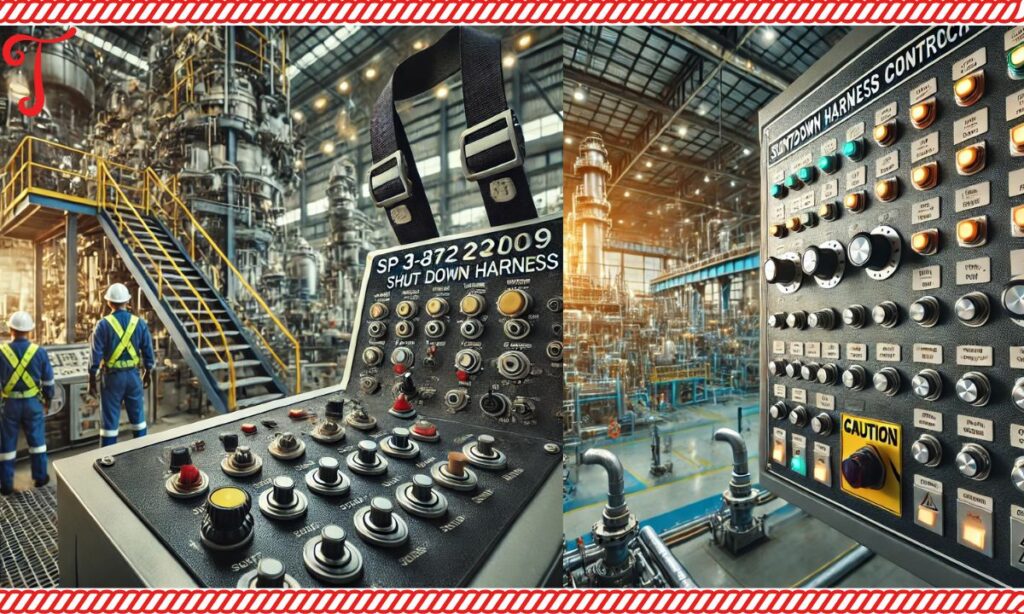

Operational Mechanics: How It Works

The ACTT harness operates through a series of coordinated steps. First, sensors detect abnormalities in the system. These sensors are strategically placed throughout the facility.

Next, the control unit evaluates the sensor data. If a shutdown is needed, it activates the relay system. This system then halts operations quickly and safely.

Installation and Maintenance: A Step-by-Step Guide

Here’s a bullet point list for “Installation and Maintenance: A Step-by-Step Guide” related to creating and maintaining a Trader Joe’s food code shopping list in Excel:

• Installation:

- Download and install Microsoft Excel if not already available

- Create a new Excel workbook for your Trader Joe’s shopping list

- Set up basic spreadsheet structure with columns for item name, food code, category, and price

- Add additional columns as needed (e.g., seasonal, favorite, quantity)

- Format headers and apply basic styling for readability

- Save the file with a descriptive name in a easily accessible location

• Initial Setup:

- Gather initial product information from Trader Joe’s (names, food codes, prices)

- Input data for frequently purchased items

- Organize items by category or store layout

- Apply basic formulas for price calculations and totals

- Set up auto-filters on column headers for easy sorting

• Data Population:

- Visit Trader Joe’s to collect more product information

- Add new items to the spreadsheet regularly

- Update prices and availability of existing items

- Note any seasonal or limited-time products

• Formula Implementation:

- Create sum formulas for category and total spending

- Set up conditional formatting for price changes or low stock alerts

- Implement VLOOKUP or INDEX-MATCH for easy item reference

• Advanced Features:

- Create dropdown lists for categories using data validation

- Set up pivot tables for shopping habit analysis

- Implement macros for repetitive tasks (if comfortable with VBA)

• Customization:

- Adjust column widths and row heights for optimal viewing

- Apply color coding for different categories or priorities

- Create separate sheets for different purposes (e.g., meal planning, price tracking)

• Maintenance:

- Regularly update product information and prices

- Remove discontinued items or mark them as unavailable

- Backup your file regularly to prevent data loss

- Optimize spreadsheet performance by removing unnecessary formatting or data

• Sharing and Collaboration:

- Save the file to a cloud service for easy access across devices

- Set up sharing permissions for family members or roommates

- Create a system for collaborative updates and changes

• Troubleshooting:

- Regularly check for formula errors or inconsistencies

- Verify data accuracy, especially after major updates

- Address any sync issues if using cloud storage

• Optimization:

- Regularly review and refine your spreadsheet structure

- Remove unused features or columns to keep the file lean

- Seek user feedback if sharing with others and make improvements

• Learning and Improvement:

- Stay updated on new Excel features that could enhance your list

- Explore online resources and tutorials for advanced Excel techniques

- Continuously refine your process based on your shopping experiences

.

Common Issues and Solutions

Even well-designed systems can face challenges. Signal interference is one common issue. This can be addressed by properly shielding signal paths.

Component failure is another potential problem. Regular maintenance helps prevent this. When issues do occur, quick replacement of faulty parts is crucial.

Main Applications and Future Prospects

The ACTT SP 3-872-009 is widely used in high-risk industries. These include chemical plants and oil refineries. Its application is likely to expand in the future.

Emerging technologies may enhance the system’s capabilities. This could include more advanced sensors or AI integration. These advancements will make the harness even more valuable.

Frequently Asked Questions

What industries benefit most from the ACTT SP 3-872-009?

High-risk industries like chemical processing, oil and gas, and manufacturing benefit most.

How often should the system be tested?

Regular testing is recommended, typically monthly or quarterly depending on usage.

Can the ACTT SP 3-872-009 be customized for specific needs?

Yes, the system is modular and can be customized to fit various industrial requirements.

What happens if there’s a power failure?

The system includes a dedicated power supply unit to function during main power failures.

How does the ACTT SP 3-872-009 compare to other shutdown systems?

It offers rapid response, scalability, and robust design, often exceeding industry standards.

Conclusion

The ACTT Service Program SP 3-872-009 Shut Down Harness is a critical safety tool. It offers rapid response to potential hazards in industrial settings. The system’s design prioritizes reliability and efficiency in emergency situations.

Implementing this harness can significantly enhance safety compliance. It also helps minimize downtime and reduce long-term costs. As industries evolve, tools like the ACTT SP 3-872-009 will become increasingly important for maintaining safe and efficient operations.

Sahar is a talented content writer and digital marketer with expertise in SEO, social media management, and online marketing. She excels at creating impactful, data-driven content to help businesses connect with their target audience and achieve measurable outcomes.